The company

Learn more about LÜLING: it’s history, culture and sustainability.

TAKING WIRE TO A NEW LEVEL

As one of the leading steel mill-independent wire drawing companies in Europe, we are your reliable partner for cold heading wire. As the sixth generation of a family-run company, we can look back on a rich tradition and extensive experience in wire drawing. We serve customers in numerous industries worlwide with our high-quality wires.

We put you, the customer, at the center of all our activities. We are convinced that an uncompromising focus on the wishes and requirements of our customers is the basis for sustainable stability and success. That is why we use our many years of experience, qualified specialists and state-of-the-art technology to constantly optimize service and quality.

We produce wires according to your individual wishes and requirements in our state-of-the-art production facilities in Altena and Iserlohn. At LÜLING, we are also happy to offer you comprehensive technical advice in order to produce the right pre-material for an efficient forming process. From innovative new developments to tried and tested products, we are at your disposal with a team of qualified and motivated employees.

Corporate culture: We have a good connection

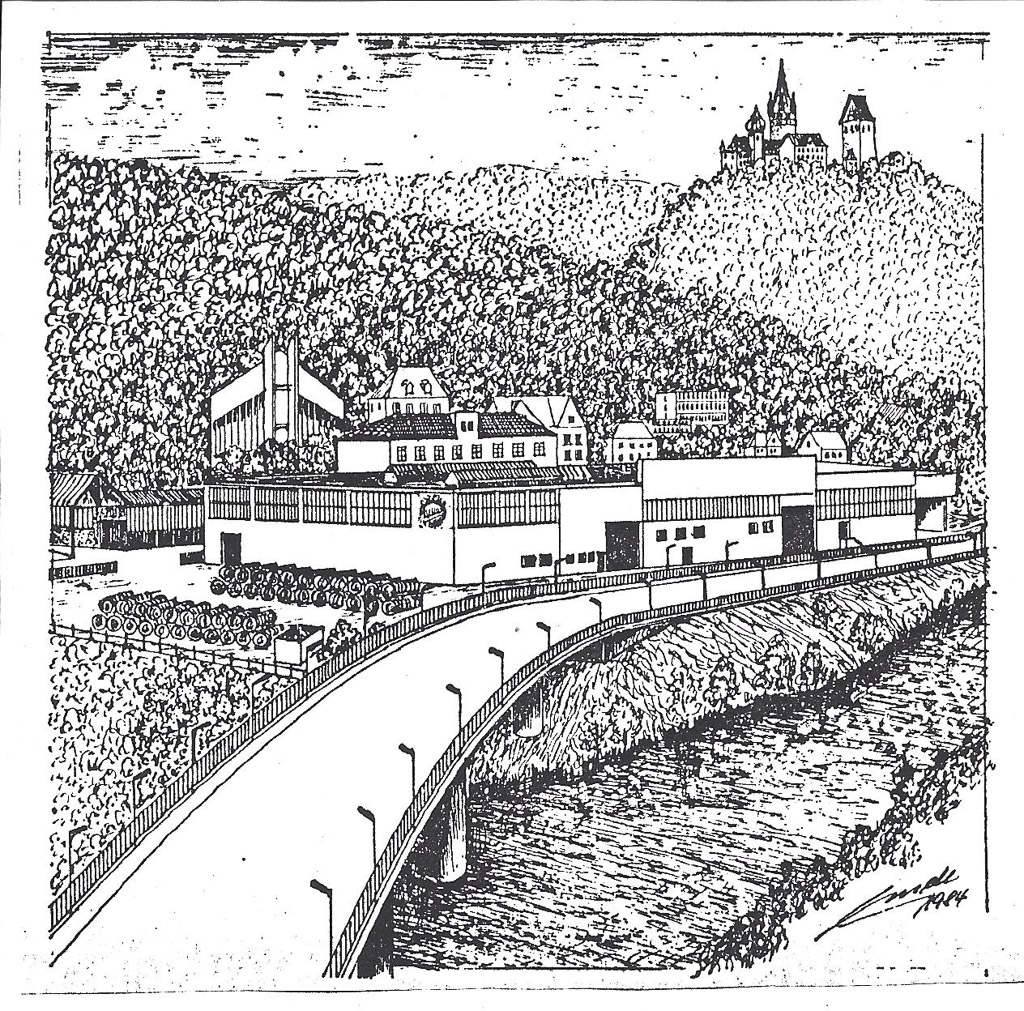

The Sauerland region, in particular the “Wire Capital of the World” Altena, is the birthplace and heart of the German wire industry. We are proud of this tradition and feel deeply connected to our region and the industrial area of South Westphalia. This is also reflected in our workforce: although we operate internationally, the majority of our employees come from the region.

We value flat organizational structures and fast decision-making processes, and we are in constant communication with our employees. In return, our employees demonstrate a high degree of individual responsibility and performance awareness. We are convinced that passion and commitment go hand-in-hand with a secure and challenging workplace and attractive remuneration. We have a good relationship with our employees. And this is reflected in the quality and reliability of our products.

This corporate culture has proven itself over generations and is constantly evolving. This is particularly appreciated by our customers worldwide. In addition, we offer young people the opportunity to learn a wide range of professions in a professional environment as part of our training activities – including, of course, “wire drawing” as part of the apprenticeship to become a metal technology specialist.

Our management:

COMMITTED TO MAINTAINING A GOOD REPUTATION

From left to right: Fabian Schmidt (Managing Partner), Stefan Sindermann (Head of Technology and Quality), Sandra Poppek (Head of Human Resources), Christian von der Crone (Managing Director) and Marc Haufer (Management, Sales, Marketing & WD Purchasing).

The LÜLING management: Fabian Schmidt – Managing Partner (right) – and Christian von der Crone – Managing Director.

Sustainable commitment: for the region & our environment

As a company, we take our responsibility towards the region and the environment seriously. Through close cooperation with universities, vocational colleges and training centres, we strive to promote a sustainable future for our region. This includes careful training of the next generation, cooperation with local schools and support for social projects.

For us, safeguarding the future also means protecting the environment: it is important to us to always pursue the most ecologically sound solution, use resources efficiently and reduce emissions. That’s the reason why we have held ISO 14001 environmental certification for more than 20 years. In 2015, we were successfully certified according to ISO 50001 for energy management.

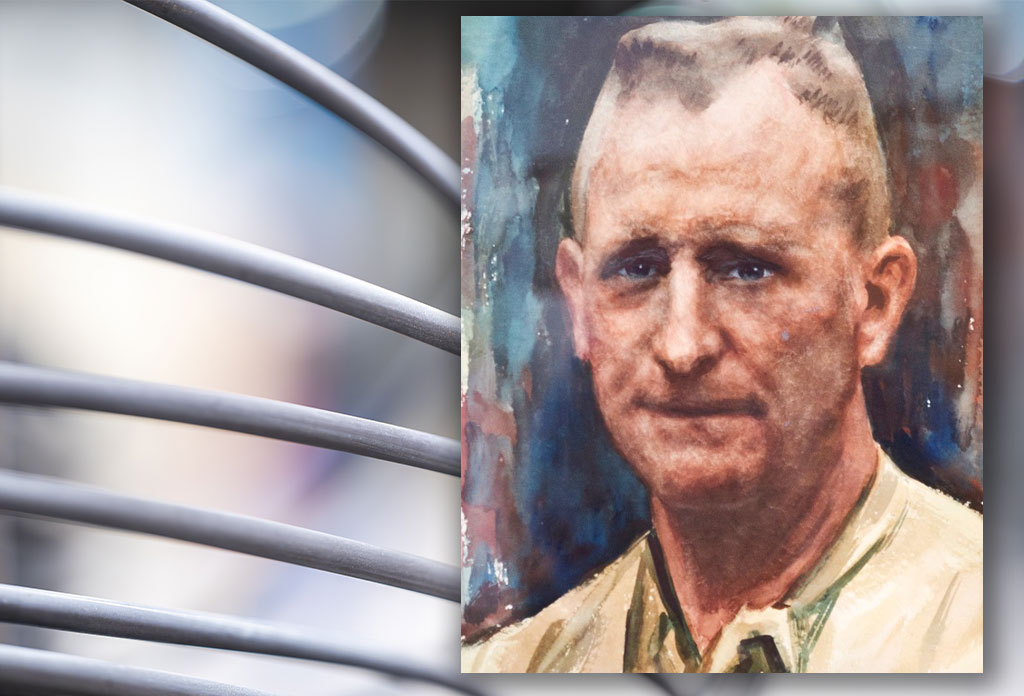

History: experience with wire since 1857

The company was founded by Friedrich Wilhelm Lüling in Altena, Nette suburb, for the production of needle wire

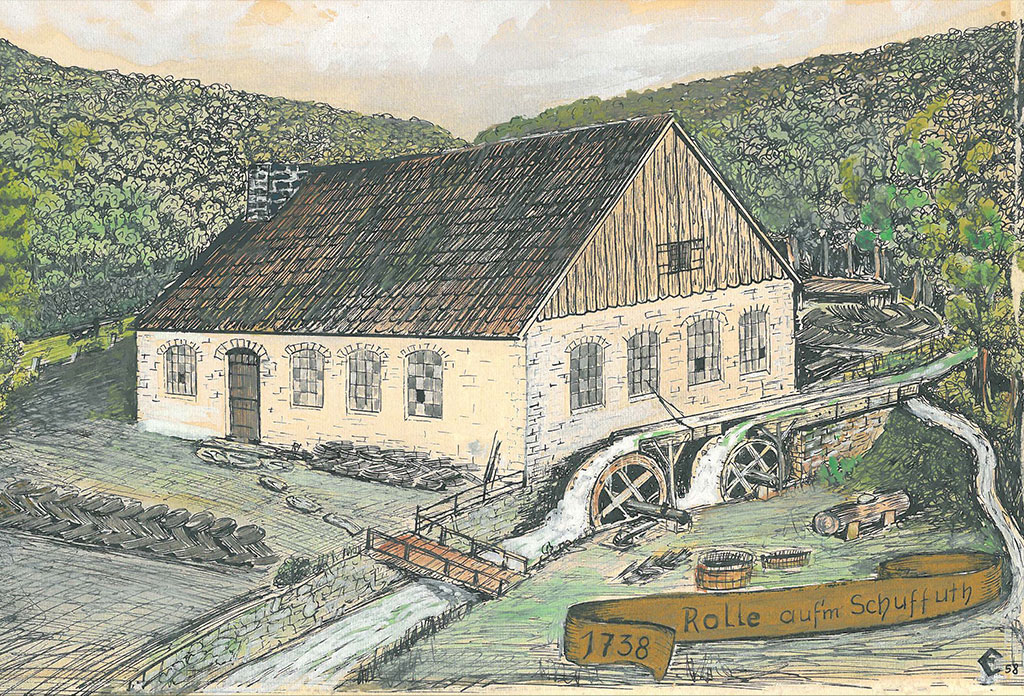

Acquisition of factory “Auf’m Schuffuth

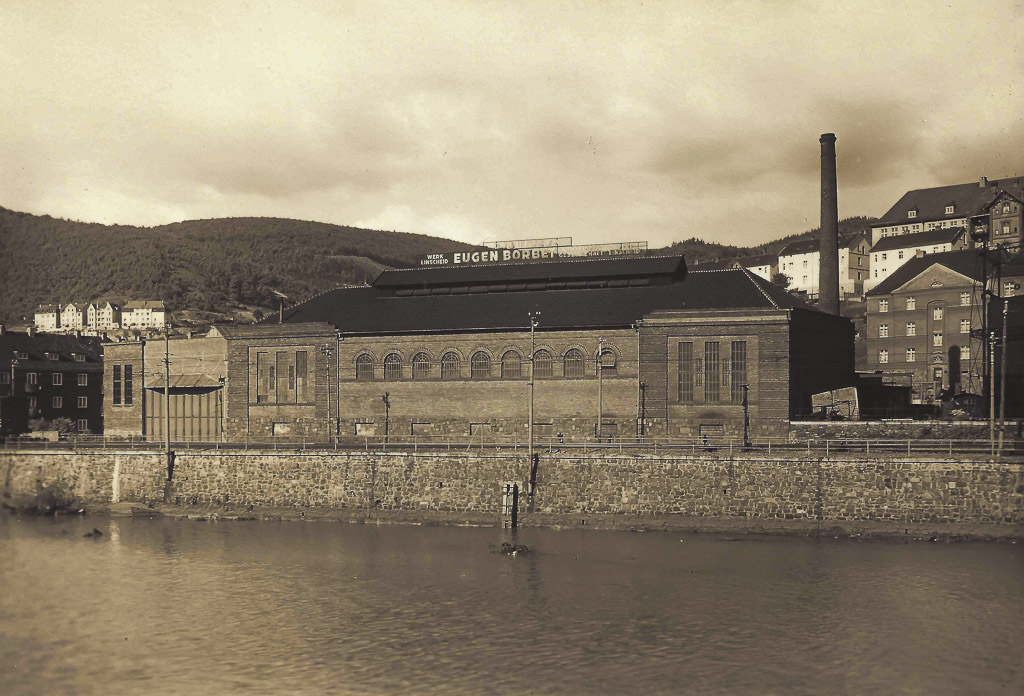

Acquisition of the Borbet company in Altena, Linscheid suburb, with production at the Nette and Linscheid plants

Implementation of the first semi-automatic surface treatment system at the Altena-Linscheid plant

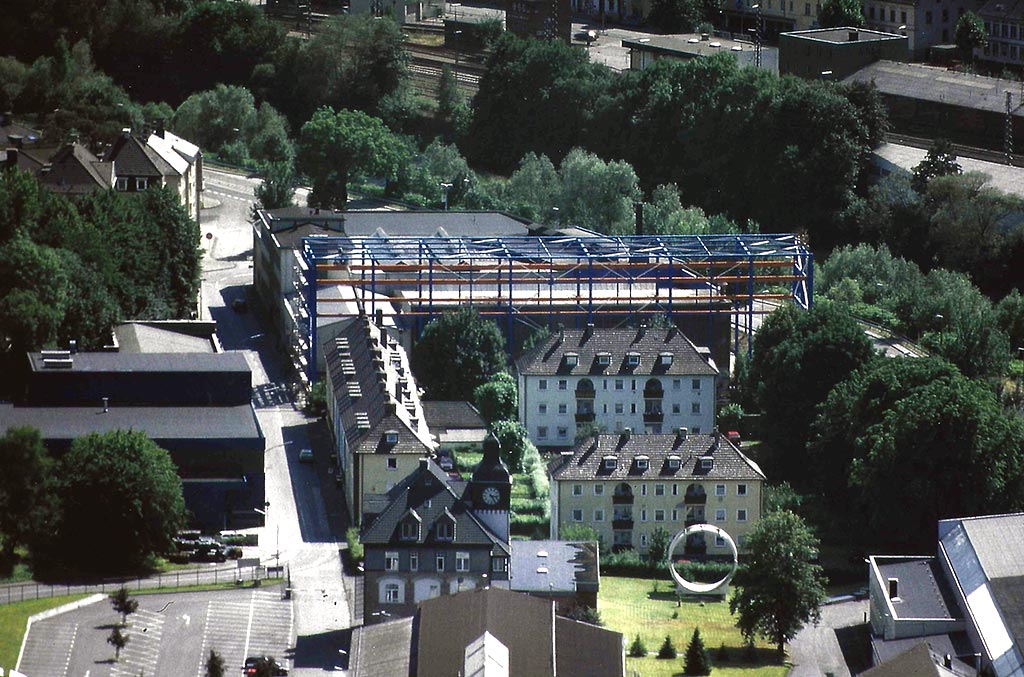

Start of production with new annealing systems at the Linscheid plant (photo: plant under construction, 1993)

Takeover of HELLWIG-Draht GmbH, Iserlohn, for the strategic expansion of the company

Expansion of annealing capacities through investment in new annealing furnaces at HELLWIG-Draht

Construction of a new surface treatment plant with a wire rod logistics centre at the Iserlohn plant

LÜLING celebrates its 150th anniversary on July 12, 2007

Completion of the new quality department and staff common rooms at the Iserlohn plant

Construction of a new surface treatment facility with a wire rod logistics centre at the Altena plant

Integration and commissioning of the first fully automatic ring binding system for steel and PET strapping

Improvement of surface defect detection with the latest generation of rotating eddy current sensors